Solutions > Print, Pack & Activate >

Product Digitization & Activation at Scale

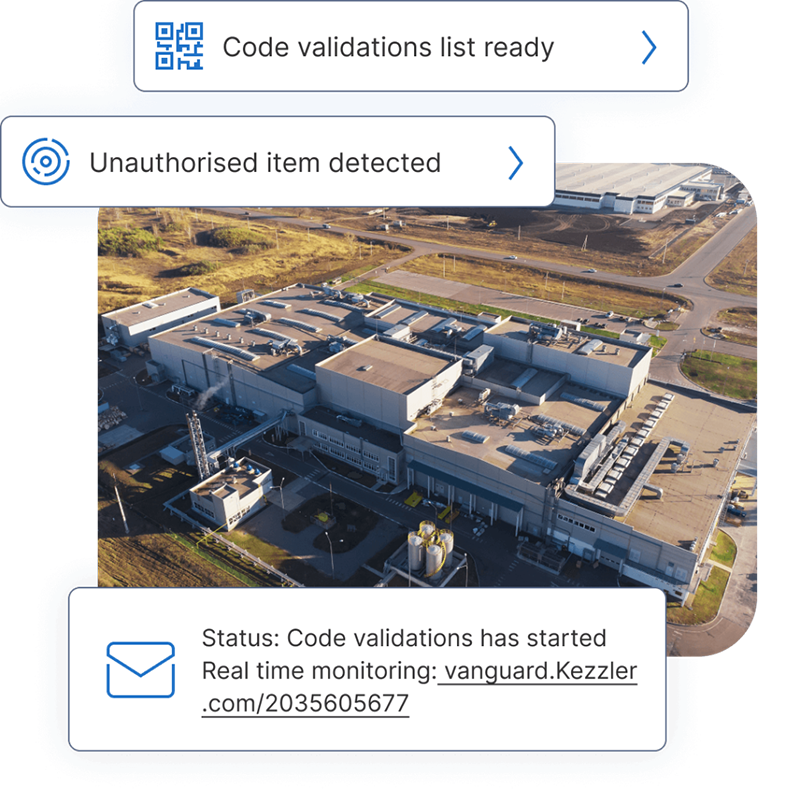

Kezzler´s traceability platform consists of a rich set of APIs and modules for printing and activation of UIDs. For easier integration, we support the EPCIS standard and our APIs are highly customizable to suit any production environment.

Kezzler has experience in integrating our enterprise solution (level 4) in a variety of production environments, ranging from manual repacking lines to fully automated, high volume production lines.

How it works

Print Codes

Apply digital identities to each individual product.

Associate Data

Associate product information and activate product.

Build hierarchies

Build packaging hierarchies and add tracking information.

Production integrations

No two integrations to production environments are the same. Our platform is built to be flexible so it can adapt to our customers’ changing requirements.

We have worked with customers where the production process requires printing, activating and aggregating on one production line, and customers where these are split between multiple production sites.

We support GS1, EPCIS for standards based integrations, or customized integrations based on RESTful API and JSON data interchange.

Selected Modules

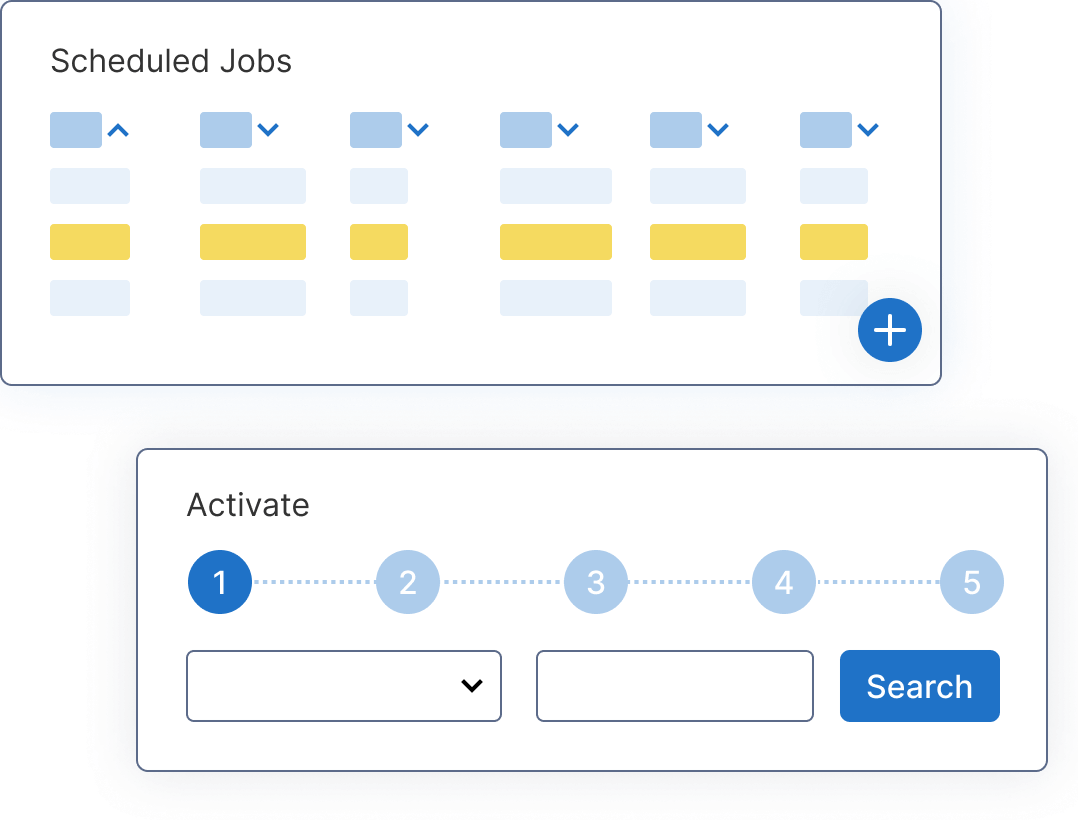

Kezzler Prepare & Activate

Easy-to-use tools allowing clients to serialize at low cost through pre-serialization. Kezzler Prepare is used to create and register rolls at label printer, while Kezzler Activate enables activation of products at any point. Product metadata can be associated to each code once activated.

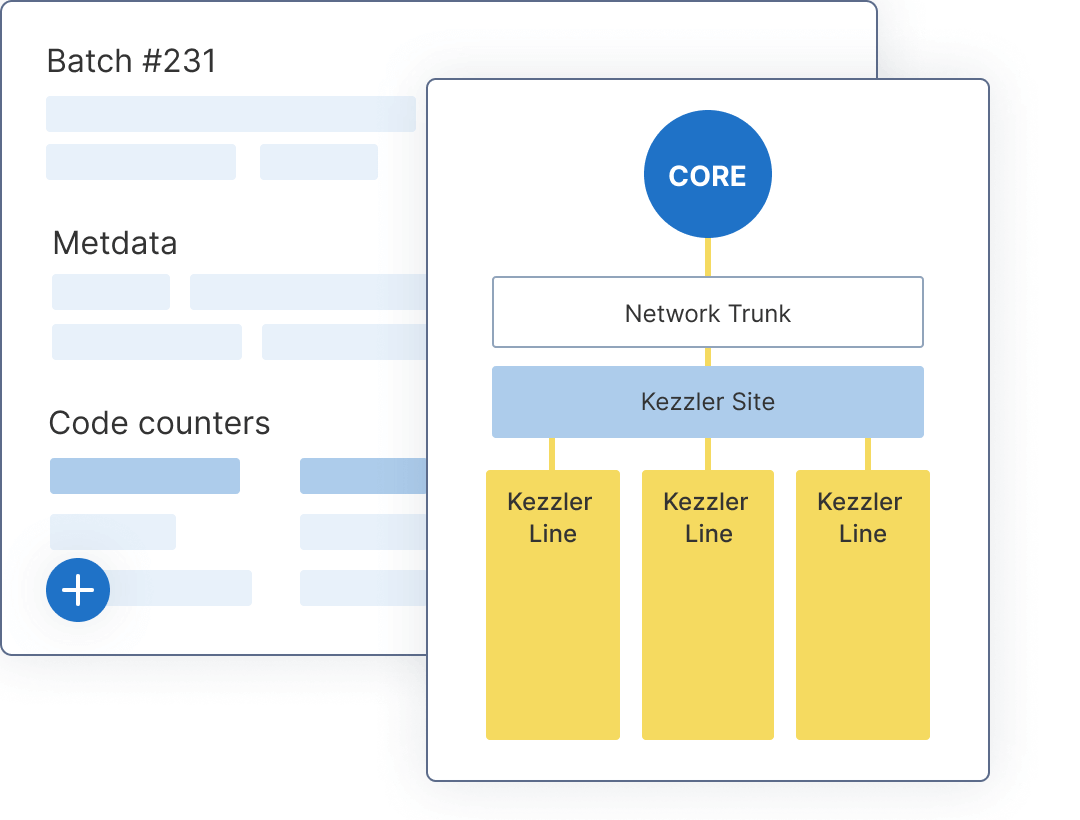

Kezzler Site & Line

Proprietary Level 2 & 3 serialization software that

enables activation and real-time, in-line printing of UIDs, together with creation of packaging hierarchies. Integrates with MES and ERP systems and is compatible with major industrial printing and vision systems.

Pre-serialization

Kezzler technology offers the unique flexibility of Pre-Serialization from the label or packaging provider through a cloud hosted Kezzler Prepare solution with minimum implementation effort. Considering all aspects, like equipment and manufacturing rejection rate, Pre-Serialization can be a substantial cost saver.

Integration Examples

Production related Insights

Production statisitcs

- Production statistics across locations

- SKU based production overview

- Production trends over time

- Product types and intended markets

Frequently asked questions

Kezzler integrates via APIs. We mainly prefer to use standard EPCIS formats for data exchange, but we can also support native formats if that is more convenient for our customers.

As a technology provider, Kezzler does not take care of the code application but offers several options as to who will print the codes. Through our ecosystem of partners, we can provide a combined offer in order to print the codes on the product (with Arca, If Labels, Matthews, Domino or VideoJet for example) or the codes can be directly included in the packaging (MaXQ with Amcor). Finally, if the brand owner does not wish to go for one of those options, as our codes are carrier agnostic, any printer should be able to apply them to the product.

As a technology enabler and platform, Kezzler only provides the UIDs and does not take care of printing them on the products. However, through our ecosystem of partners we are able to provide joint offers, either printing on your product (with Arca, If Labels, Matthews, Domino or VideoJet for example) or as a connected packaging solution (MaXQ with Amcor). Kezzler technology also offers the unique flexibility of Pre-Serialisation from the label or packaging provider through a cloud hosted Kezzler Prepare solution with minimum implementation effort. Considering all aspects, like equipment and manufacturing rejection rate, Pre-Serialisation can be a substantial cost saver.

In short no, with Kezzler you can also serialise on Batch and SKU level. Contact us for more details.

Track & Trace

End-to-end unit level traceability

Contact us

Not sure of the differences between pre-serialization and in-line serialization? Get in touch to discuss which option is best for you.

Kezzler

Get more details