End-to-end unit level traceability

By tracking an individual product’s unique journey through each step of the supply chain, brands can proactively use real data and insights to resolve issues related to product sustainability, production efficiency, regulatory compliance and risk.

To enable unit-level product traceability across the supply-chain, Kezzler has developed a rich set of APIs based on EPCIS standard in addition to applications for manual track and trace and supply-chain inspections.

How it works

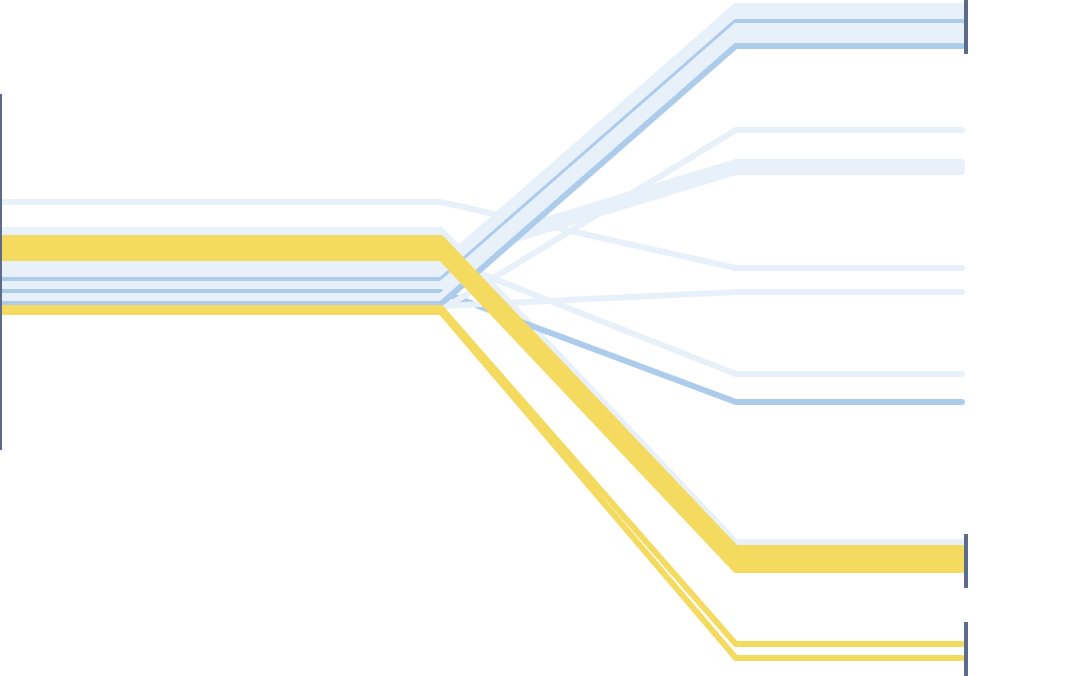

SSCC Hierarchy

Connect product items to pallets and/or containers for tracking.

Shipping & receiving

Track your pallets/ containers through the supply chain.

Point of sales

Integrate at POS to gain insights and incentivize retailers.

Supply Chain Integrations

To implement unit level traceability with low operational burden, Kezzler´s Track & Trace solution is architectured around GS1 EPCIS standard.

The platform supports all GS1, EPCIS business steps and dispositions for ease of integration with any logistics infrastructure. We support SAP integrations through ASN and RECADV.

To simplify the implementation of unit level traceability, our platform can include excisting SSCC codes from pallets and containers in the packaging hierarchies.

Additional Modules

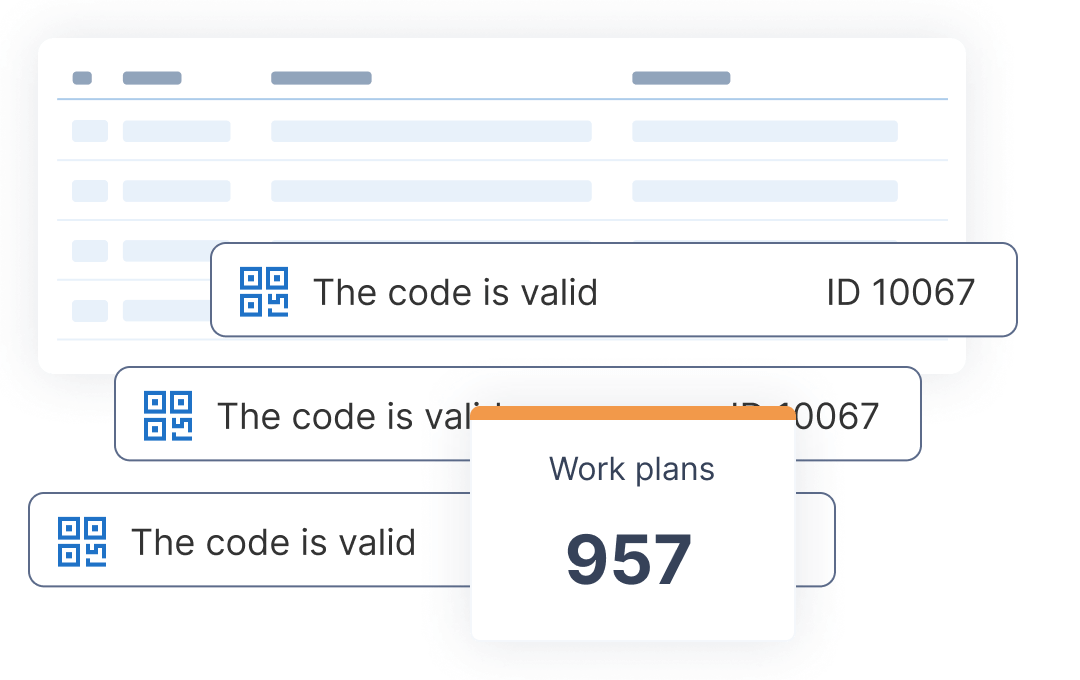

Kezzler Track App & Web

A lightweight tool enabling simple and rapid deployment of aggregation and tracking operations in low automation environments. The application is paired with a web interface allowing brand owners to pre-configure an unlimited number of activities related to pick-and-pack, distribution and hierarchy- management.

Kezzler Inspect

Create, manage and execute marketplace inspection programs to detect challenges in your supply chain. Kezzler Inspect is based on an administration web UI in combination with an Android app for inspectors. Through a lightweight web interface, centralized inspections can be done anywhere in the world with unlimited inspectors.

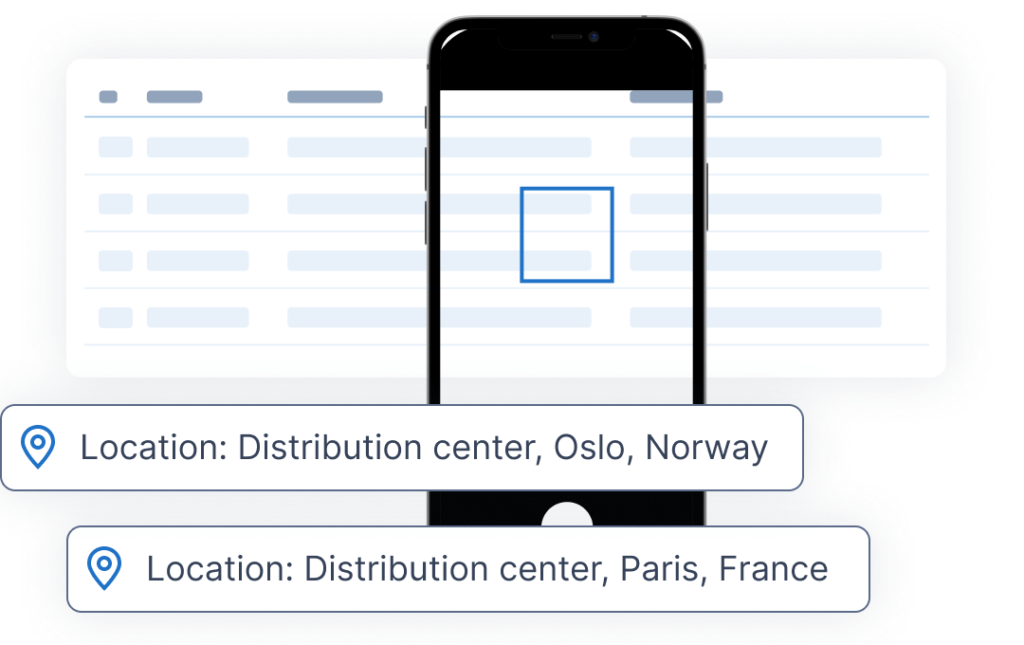

Kezzler Geofence

Enhance detection of product deviations and unauthorized distribution. Geofence provides a new level of granularity: depending on the region or country in question, geofencing rules can be defined even at the county-level (or equivalent).

Kezzler Recall

Improve the recall process, reduce waste and better inform the consumers. With targeted product recalls, you can proactively alert consumers scanning the product and register the returned products on unit level.

Integration Examples

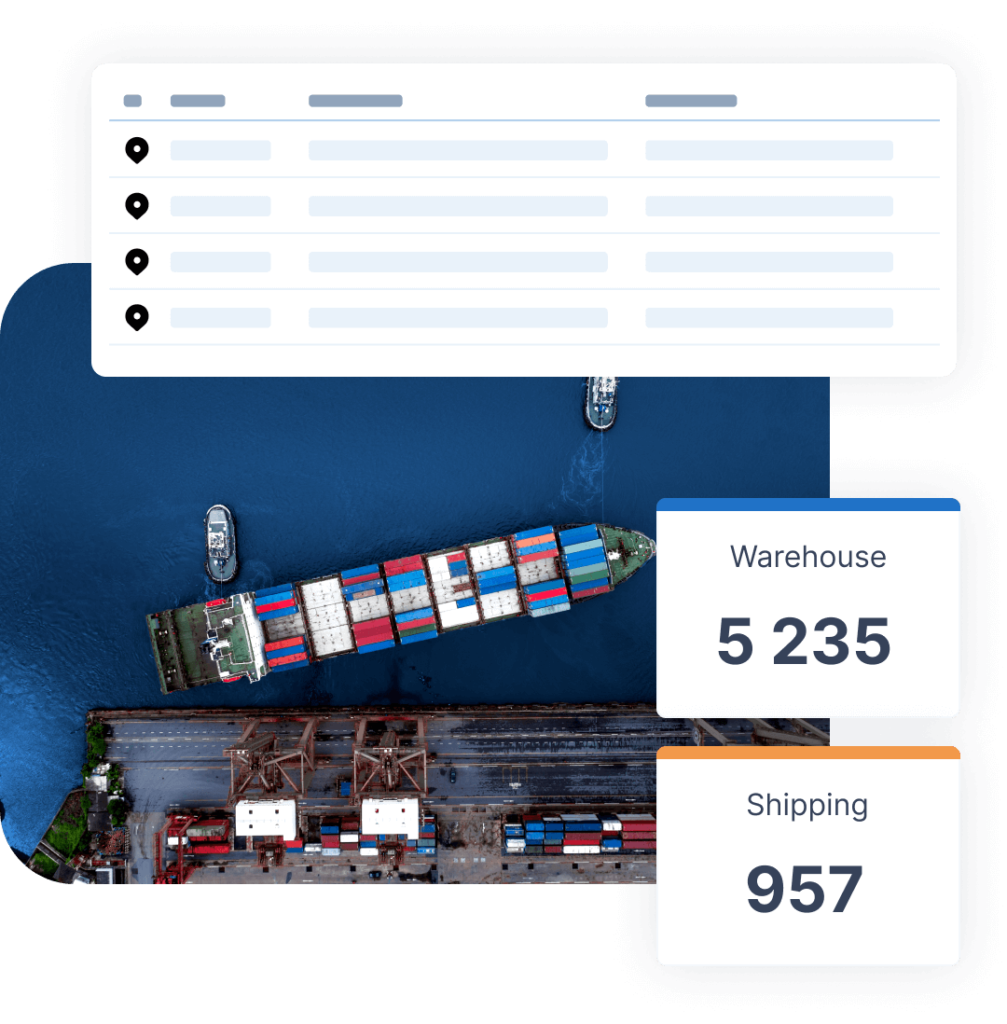

Supply Chain related Insights

Business location based insights

- Current inventory overview

- Trends of time spent at locations

- Global overview of SKUs in supply chain

Non-Conformity related insights

- Product diversion within supply chain

- Deviations from intended product journeys

Business location based insights

- Overview of products by production batch

- Product journey trends over time

- Recall oversight and tracking

Frequently asked questions

Track and trace solutions allow brands to track an individual product’s unique journey through each step of the supply chain. Brands can proactively use real data and insights to resolve issues related to product sustainability, production efficiency, regulatory compliance and risk. Kezzler technology has been designed so that all participants in the supply chain can mark and track products with minimum possible impact on their operations; without expensive IT-installations, hardware or personnel training. In practice the Kezzler solution has greatly simplified the nature of these implementations.

The Kezzler track and trace solution ensures the product link to a brand is never broken, from manufacturing all the way to the consumer. Making every product unique, makes it possible to trace and select only those products that require recall. If a product is causing an issue in the market, a quick scan reveals its history. There might be nothing wrong with the batch, only one leg of transportation, for example, saving you vast costs trying to put right what isn’t wrong. Or if a specific batch needs recalling, you know exactly where these products are in your distribution chain and can begin minimising damage.

A transparent supply chain, with the ability to trace products throughout the entire product lifecycle from raw material to end consumer, can greatly enhance supply chain visibility and insight. The Kezzler cloud-based traceability platform enables brands to achieve a compliant, secure and transparent supply chain. Additional value is created through improved internal processes, better decision making through new insights and an enhanced consumer experience through augmented products.

Kezzler accepts several ways of knowing where the scans are taking place, depending on our clients’ needs and what it is willing to provide us. Those forms of localisation can for example be the IP address, geolocation, location ID or a country code.

Consumer Engagement

Your Product is a New Key Touchpoint

Contact us

Track and trace products from creation to consumption, collecting data through the product journey and the entire product life cycle.

Kezzler

Get more details